CONE CRUSHER PARTS

Cone Crusher has the features of large crushing ratio, high efficiency, low energy consumption, and uniform product size. It is suitable for medium and fine crushing of materials with medium and above hardness.

It is usually used for secondary and tertiary crushing of ores and rocks. Cone crushers are widely used in many industries such as mining, smelting, building materials, highways, railways, water conservancy and chemical industries.

During the working process of the cone crusher, the motor drives the eccentric shaft to rotate through the transmission devices. The mantle rotates and swings under the forced movement of the eccentric shaft. The section of the mantle close to the concave becomes the crushing cavity.

After being pressed and impacted by them, the material is broken and discharged from the bottom of the cone crusher due to gravity.

WEARING PARTS FOR CONE CRUSHER

Obviously, the most frequent wearing parts in cone crusher are the mantle and concave. The metallurgy of MINREQ standard cone crusher liners range from: Mn13Cr2, Mn18Cr2 and Mn22Cr2 according to your application. Our massive database and mold inventory ensure that you can get any crushing cavity of most popular cone crushers.

According to the usage and customer's feedback under various working conditions, GTEK® cone crusher wear parts have a service life of 10-15% longer than other suppliers.

Except mantle and concave, other wear parts such as: Feed Cones, Main Frame Liners, Arm Guards, Distribution Plate... are also in our supply range.

Genuine Alternative Cone Crusher Spare Parts

MINREQ also manufacture and stock precision-machined forgings, bronze parts such as main shafts, head centres, socket liners and eccentric bushings for popular cone crushers.

In addition to this, our large lathes and own foundry allow us to provide premium frames at a more competitive price, including the main frame, top and bottom shells.

Our vast inventory also includes the spare parts for the hydraulic and lubrication system, such as replacement gaskets, filters and seals as well as the complete new lubrication assemblies and hydraulic panels.

CONE CRUSHER PARTS in our scope of supply :

• Main Frame

• Main Shaft

• Adjustment Ring

• Clamping Ring

• Dust Shell

• Counter Shaft

• Counter Shaft Box

• Counter Shaft Box Guard

• Counter Shaft Bushing

• Pinion

• Oil Flinger

• Eccentric

• Eccentric Bushing

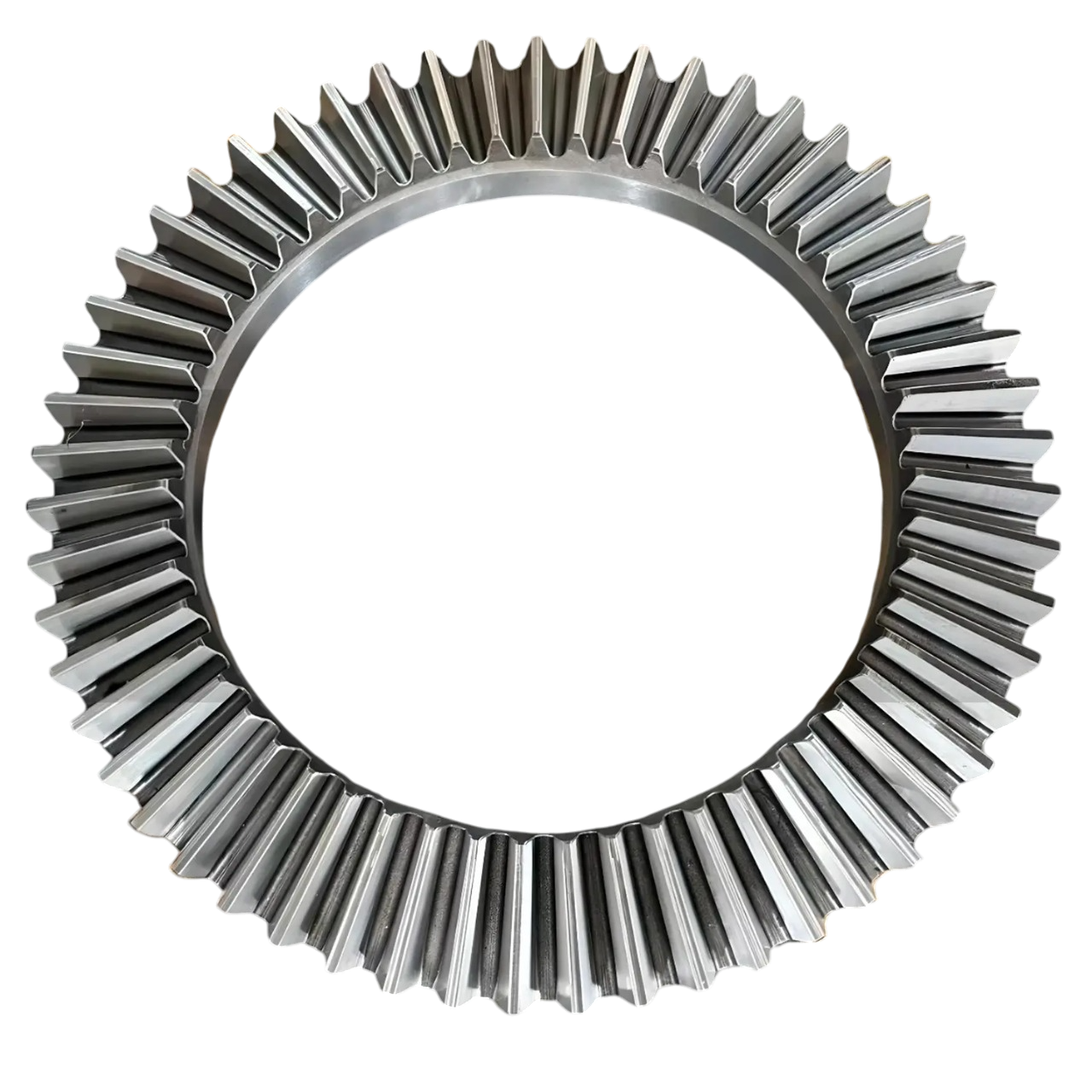

• Gear

• Thrust Bearing

• Counterweight

• Counterweight Guard

• Socket

• Socker Liner

• Head

• Head Ball

• Thrust Bearing

• Locating Bar