W - Series Slurry Pump

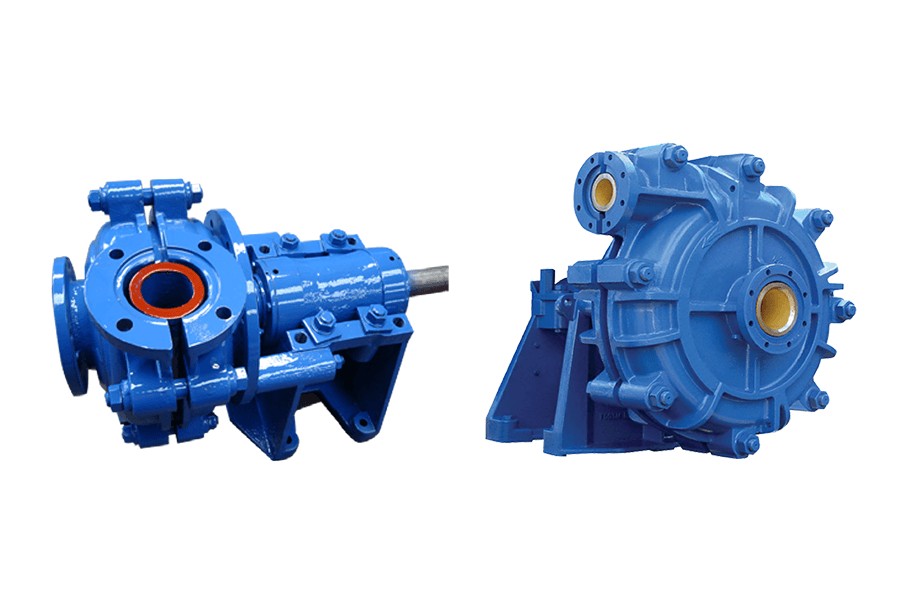

The MINREQ M-AH pump range, designed for heavy-duty applications, continuously evolves to enhance performance while maintaining quality.

It efficiently handles highly abrasive, dense slurries in mineral processing, including hydro cyclone feed, flotation, and tailings.

MINREQ M-AH Pump Design Features and Benefits

- Heavy-duty construction with through-bolt design ensures ease of maintenance and minimal downtime.

- Ductile iron fully lined casing provides durability, strength, safety, and long service life.

- Cartridge-style bearing assembly allows maintenance in a clean environment without pump removal, ensuring reliable operation and prolonged bearing life.

- Grease or oil lubrication bearing assembly options enhance maintenance ease and reduce downtime.

- Large diameter, slow-turning, high-efficiency impellers maximize wear life and minimize operating costs.

- Large, open internal passages reduce internal velocities, extending wear life and lowering costs.

- Thick elastomer or alloy bolt-in liners offer superior corrosion resistance, easy change-out, and interchangeability to reduce maintenance costs and maximize wear life.

- Minimal shaft/impeller overhang reduces shaft deflection, increasing packing life.

- Optional dry running shaft seal reduces or eliminates flush water requirements.

- Effective expeller prolongs packing life while minimizing flush water needs.

- MINREQ throatbush and impeller combination enhances efficiency and improves wear performance.

- Interchangeable seal arrangements (full flush, low flow, centrifugal, or mechanical seals) fit any pump size for versatile application.

M-AH Pump

M-AH Pump

M-AH Pump

*NOTE: All manufacturer names, part numbers, model numbers, and descriptions are used for reference and identification purposes only, they are owned by the respective machine manufacturer. All parts supplied are manufactured and warranted by MINREQ and are not manufactured by or purchased from the Original Equipment Manufacturer. MINREQ has no association with the OEM and does not intend to give this impression.

Typical Applications

Heavy duty pumping applications The heavy duty M-AH pump range is designed to perform continuous pumping of highly abrasive/ dense slurries in processes from hydro cyclone feed to regrind, flotation and tailings in minerals processing plants as well as other industrial applications.

- Ball mill discharge, Bottom/fly ash, Lime grinding, Coal, Coarse sand, Coarse tailings

- Dredging, FGD, Fine tailings, Flotation, Heavy media, Minerals concentrate

- Mineral sands, Ni acid slurry, Oil sands, Phosphoric acid, Phosphate matrix,

- Process chemical, Pulp and paper, Rod mill discharge, SAG mill discharge, Wet crushers

Metal Lined Slurry Pumps

The M-HHS range pump is specifically for persistent use in slurry type applications where a high head per stage is required. The range is capable of handling heavy duty, medium size particles and pumping at heads in excess of 90 meters per stage. The small eye to impeller diameter ratio provides a combination that yields perfect wear performance.

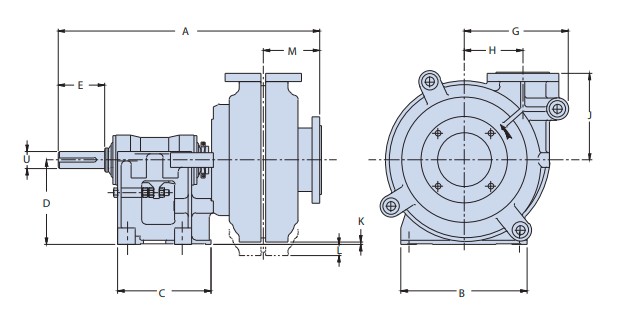

Specification: Size range (outlet): 1" to 18" 25 mm to 450 mmCapacities: to 22,000 gpm to 5,000 m3/hrHead: to to 240 ft / to 73 mt

.png)

Metal Lined Slurry Pumps Features

- Bearing assembly: A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

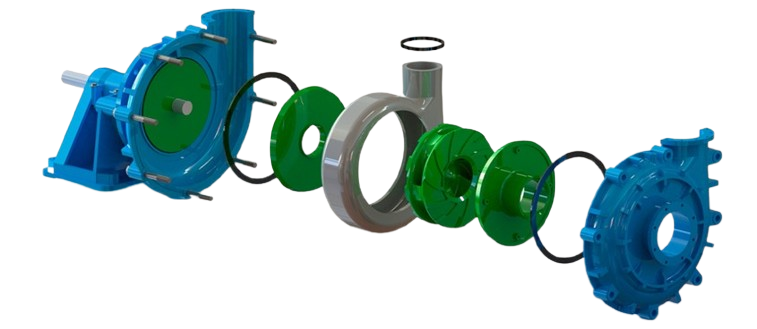

- Liners: Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

- Casing: Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

- Impeller: Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

- Throatbush: Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

- One-piece frame: A very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance.

Common W - Series Slurry Pump in our scope of supply :

- Labyrinth lock nut

- Shaft

- Bearing housing

- Grease retainer

- Bearing

- End cover

- Labyrinth

- End cover screw set

- Gland packing

- Shaft sleeve

- Lantern restrictor

- Shaft spacer

- Clamp washer

- Adjusting screw

- Clamp bolt

- Frame plate stud

- Frame plate

- Cover plate bolt

- Stuffing box

- Seal

- Volute seal

- Frame plate liner insert (metal or rubber)

- Volute liner

- Impeller (metal or rubber)

- Throatbush (metal or rubber)

- Volute seal

- Cover plate

- Cover plate nut

- Gland assembly

- Gland bolt

- Frame plate liner

- Frame plate cover