HYBRID JAW

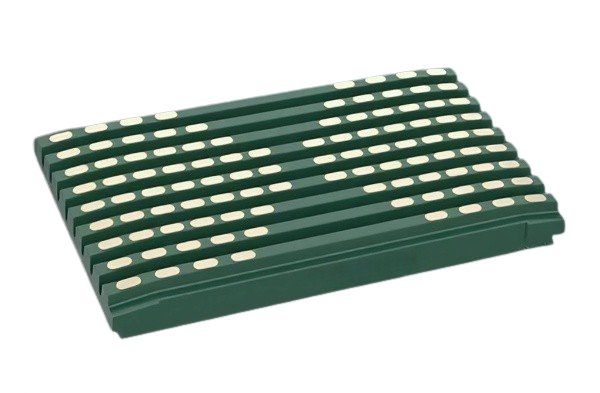

Compare with normal manganese jaw crusher liners, insert wear parts span life can be 1.5-2 times. Based on our customer feedback, the harder material to crush, the long the span life.

When increased profitability matters

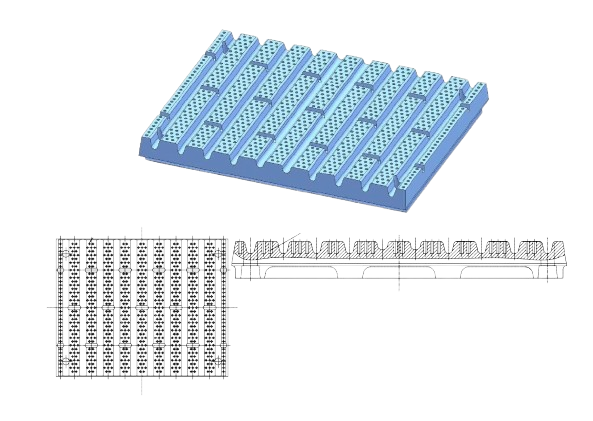

Hybrid Jaw

Hybrid Jaw

Hybrid Jaw

*NOTE: All manufacturer names, part numbers, model numbers, and descriptions are used for reference and identification purposes only, they are owned by the respective machine manufacturer. All parts supplied are manufactured and warranted by MINREQ and are not manufactured by or purchased from the Original Equipment Manufacturer. MINREQ has no association with the OEM and does not intend to give this impression.

Double the wear life of your jaws

Its unique characteristics keep the optimal wear profile longer and make the jaw extremely wear resistant. You can achieve double the wear life compared to manganese jaws, and sometimes even triple it - depending on the application.

The long wear life and reliable performance of MINREQ jaws reduces the need for inventory while at the same time minimizing service work costs. All this leads to more profit for you.

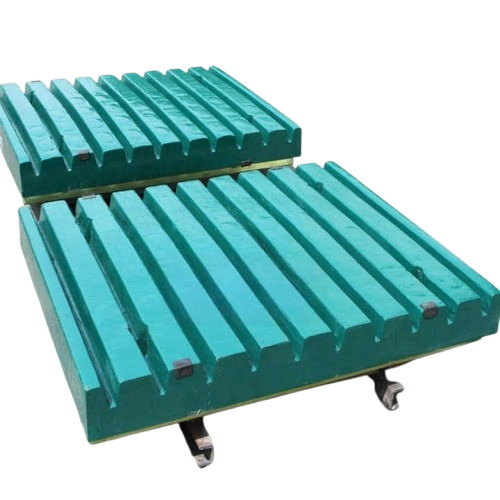

Improved safety

Using the appropriate lifting tool for a specific wear part is crucial. When installing jaws, the MINREQ jaw crusher maintenance platform and the specially designed lifting tool can be used. These tools, designed for MINREQ jaws only, improve working conditions and make it possible to carry out installations quickly and efficiently, without compromising safety.

Benefits

- One & Half or Double wear life compared to manganese jaws

- Optimized wear profile

- Fewer parts in stock

- Higher uptime

- Reduced service costs

- Improved safety due to longer change-out intervals