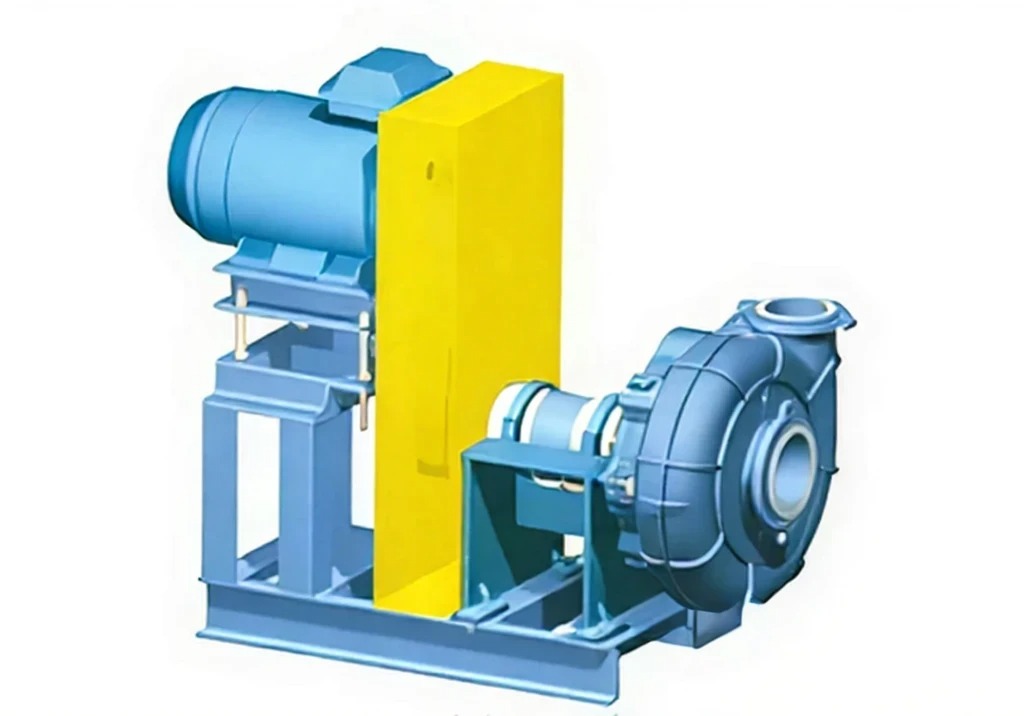

M-Series Slurry Pump

Versatile shaft sealing options, including full flow, low flow, and mechanical seals, cater to diverse operational needs. Ideal for hydro cyclone feed, tailings, and coal ash handling, M-Series pumps deliver reliable performance under harsh conditions. With customizable materials like chrome iron and polyurethane, they ensure cost-effective, long-lasting solutions for demanding slurry transfer tasks.

M -Series HM Range Pump

Made for the most arduous industrial slurry pumping applications. Consists of hard metal lined.

Designed for abrasive duties and medium heads in general plant transfer applications. Covers hard metal lined .

Typical Applications

Slurry Pump Features and Benefits

- High efficiency design.

- M-Series Range optimization ensures operation close to the best efficiency point.

- Wear parts of highest quality hard metal.

- Interchangeability of hard metal and elastomer parts to provide the best solution for each individual application.

- Specially developed features provide trouble-free operation and a minimum downtime improving the cost effectiveness.

- Durable and corrosion-resistant materials, including carbon graphite packing, to ensure long-lasting performance for sealing.

- Pumps and parts are manufactured under total quality management.

- Full flow : Use for suction conditions not suitable for centrifugal sealing when product dilution is not important. Full flow provides the longest packing wearing life.

- Low flow : Use for suction conditions not suitable for centrifugal sealing when product dilution needs to be minimized.

- Standard expeller shaft seal : Used for no product dilution against positive suction head without leakage.

- Minreq slurry mechanical seal : Used for zero stuffing box leakage or product dilution. Available as single slurry type mechanical seal or double mechanical seal with external barrier fluid required.

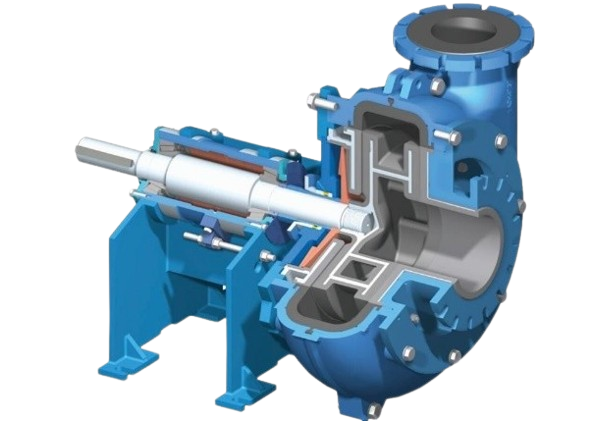

Key features and benefits M - HM series & MM Series:

The M-HM series pumps are commonly used in various industrial applications, including: Mining and mineral processing, Coal handling and processing, Pulp and paper manufacturing, and Industrial wastewater treatment.

Key features and benefits of the M - HM series:

- Rugged Construction: Designed to withstand the harsh conditions of slurry pumping, including abrasion and wear.

- Hard Metal Lined: Features hard metal wear parts for enhanced durability and resistance to wear and tear.

- Optimized Hydraulic Design: Ensures maximum efficiency and performance throughout the pump's lifespan.

- Energy Efficiency: Designed to minimize power consumption and improve overall operational efficiency.

- Reduced Maintenance: Features like easy maintenance and wear part replacement contribute to lower maintenance costs

Applications of MM Series:The Minreq MM series are horizontal slurry pumps designed for abrasive slurries, particularly in mining and mineral processing. They are available in hard metal or rubber-lined versions and are known for their reliability and low power consumption. The M-range pumps are designed for medium abrasives, lower solids concentrations, and medium heads, making them suitable for general in-plant transfer applications.

The pumps are commonly used in mining and mineral processing, highly abrasive slurry transfer, SAG and AG mill discharge, cyclone feed, mine refuse and tailings, industrial processing, coal and power plant ash, and more.

Key features and characteristics of the MM series:

- Abrasive Slurry Handling: The pumps are specifically designed to handle abrasive slurries, making them suitable for applications like SAG and AG mill discharge, cyclone feed, and mine tailings.

- Hard Metal Versions: The pumps are available in both hard metal construction, allowing for flexibility in choosing the right material for the specific application.

- Modular Design and Back Pull-out: The modular design and optional back pull-out feature facilitate easy inspection and maintenance.

- Material of Construction: They are available in both metal construction, allowing for customization to suit specific needs.

- Temperature and Pressure: They can handle temperatures up to 212F and pressures up to 232 PSI.

Here's a more detailed look:

- Design: The M-VS pumps are characterized by their large, generously sized wear parts, ensuring long-term durability.

- Materials: They offer a range of wear part materials, including Chrome Iron (SHR), Chloroprene, EPDM rubber, Polyurethane, and stainless steel for specific applications.

- Applications: MINREQ M-VS pumps are suitable for a wide range of applications, including mill discharge, tailings, and other demanding slurry applications.

- Features: The modular design of the M-VS series allows for easy maintenance and repair.