BLOW BARS

Full-Range of Metal Shredder Wear Parts

Bottom Grates

Liners

Caps (rotor and end discs)

Breaker Bars / Anvils

Reject Doors

Front Walls

Available Materials of Metal Shredder Hammers

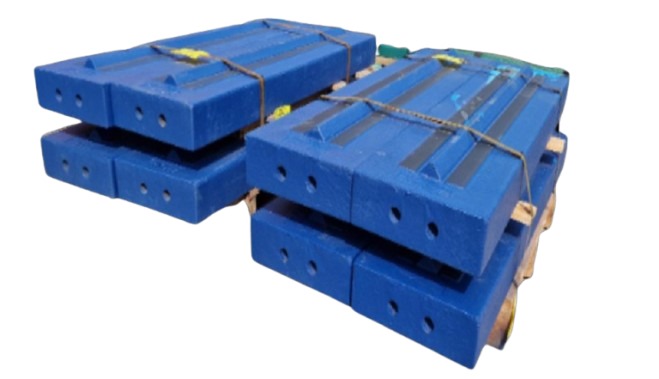

Blow Bars

Blow Bars

Blow Bars

*NOTE: All manufacturer names, part numbers, model numbers, and descriptions are used for reference and identification purposes only, they are owned by the respective machine manufacturer. All parts supplied are manufactured and warranted by MINREQ and are not manufactured by or purchased from the Original Equipment Manufacturer. MINREQ has no association with the OEM and does not intend to give this impression.

METAL & WASTE SHREDDER WEAR PARTS

CHROME STEEL

To prevent the material from becoming brittle, the blow bars must be heat-treated. It must thereby be observed that the temperature and annealing time parameters are exactly adhered to. Chrome steel typically has a hardness of 60 to 64 HRC and a very low impact strength of 10 J/cm2.

To prevent breakage of chrome steel blow bars, there may not be any unbreakable elements in the feed material.